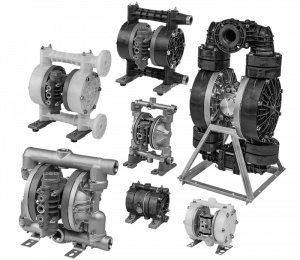

Air Operated Diaphragm Pump

Illinois Process Equipment, IPE, offers air operated diaphragm pumps that cover a wide range of applications. Air operated double diaphragm, AODD pumps, have unique capabilities to self-prime and handle more viscous, thicker materials and solids. IPE offers AODD pumps from the top manufacturers along with value-added services such as sizing, technical support, pump system design, repairs and more.

Showing all 7 results

-

Iwaki TC-X102PT-NPT Air Operated Diaphragm Pump

-

Iwaki TC-X152AT-NPT Air Operated Diaphragm Pump

-

Iwaki TC-X152VT-NPT Air Operated Diaphragm Pump

-

Iwaki TC-X152VT-PP-NPT Air Operated Diaphragm Pump

-

Iwaki TC-X202PT-FLA Air Operated Diaphragm Pump

-

Iwaki TC-X202PT-NPT Air Operated Diaphragm Pump

-

Iwaki TC-X252PS-NPT Air Operated Diaphragm Pump

Air Operated Diaphragm Pump Operation

An AODD pump consists of two pumping chambers that alternately fill and discharge from the flexible diaphragm movement. Compressed air is supplied to and then vented from air chambers which creates the pumping action. This repeated and alternate back-and-forth movement makes the strokes of the two flexible membranes. The refined distribution system of compressed air directs air to the two air chambers alternately on opposite sides of the diaphragms.

Air Diaphragm Pumps Applications

Air operated diaphragm pumps are used in transfer applications and have the capability to handle a wide range of feeds including slurries, sludges, sensitive and abrasive fluids as well as powder transfer. AODD pumps are easy to maintain and are reliable. Some of the primary uses of AODD pumps include transferring waste water generated during manufacturing processes in chemical and paint processing applications and steel mills.

You can find air diaphragm pumps in many applications including:

Paint manufacturing plants – AOD pumps help to transfer wastewater generated onsite as well as handling the transfer of paints and materials for manufacturing. Some paints have coloring with titanium dioxide that can be abrasive, AOD pumps handle these and latex paints which can be damaged by shearing.

Chemical transfer – AOD pumps help to move materials from one location to another during chemical transfer applications such as moving raw materials to holding tanks or mixing for manufacturing, as well as moving waste.

Steel mills – mills generate waste during manufacturing. AOD pumps move waste water to an onsite treatment facility to remove solids and make the water more neutral with safe pH levels to send to municipal wastewater treatment plants.

Cosmetics – AOD pumps are common in cosmetic manufacturing to move more viscous materials from drums to tanks or processing areas.

Food and beverage – AOD pumps easily transport viscous materials like tomato paste for example, from drums to tanks for food processing.

Oil and gas – air diaphragm pumps help to evacuate waste from sumps to onsite treatment facilities.

Air operated diaphragm pumps are used in these applications and can be found in nearly all applications and industries. These types of pumps are suitable in hazardous applications due to using compressed air as the power source instead of electricity. This also allows for AOD pumps to be submerged as long as the exhaust is not submerged.

Features and Benefits of Air Diaphragm Pumps

All air diaphragm pumps are self-priming, by creating a vacuum in the suction pipe. They are essentially leak-free, with only stationary seals between the outside environment and wetted parts, so a leak can occur only if one or both of the diaphragms fail. Diaphragms in AODD pumps suffer less wear and tear than mechanically driven diaphragm pumps, due to the balanced pressure supplied with compressed air. Diaphragms should be replaced regularly as part of a general maintenance program, IPE offers service for AODD pumps to maintain optimum working conditions.

One of the best benefits of AODD pumps is the ability to handle highly viscous, thick, and abrasive materials. The gentle pumping action of air diaphragm pumps makes them ideal to handle shear-sensitive fluids. AOD pumps have no internal seals and no moving components that require lubrication or cooling so they can be run dry without damage.

Air diaphragm pumps provide the following benefits:

- Self-priming

- Simple to operate

- Simple installation

- Submersible

- Portable

- Can run dry

- Handles abrasive liquids

- Provides viscous fluid pumping

- Pumps shear sensitive liquids

- Low maintenance, easy to service

- Straight forward design

IPE Offers Air Diaphragm Pumps and Service

Illinois Process Equipment, IPE, has been providing high-quality, specialty pumps and services since 1996. We focus on providing value-added products and services that encompass the entire spectrum of pumping services. IPE is set apart from other pump suppliers with our technical capabilities and turnkey solutions including complete pump system design, installation, testing, field service and in-house repair.

Contact Us Now